Using Nail Polish for Soldering

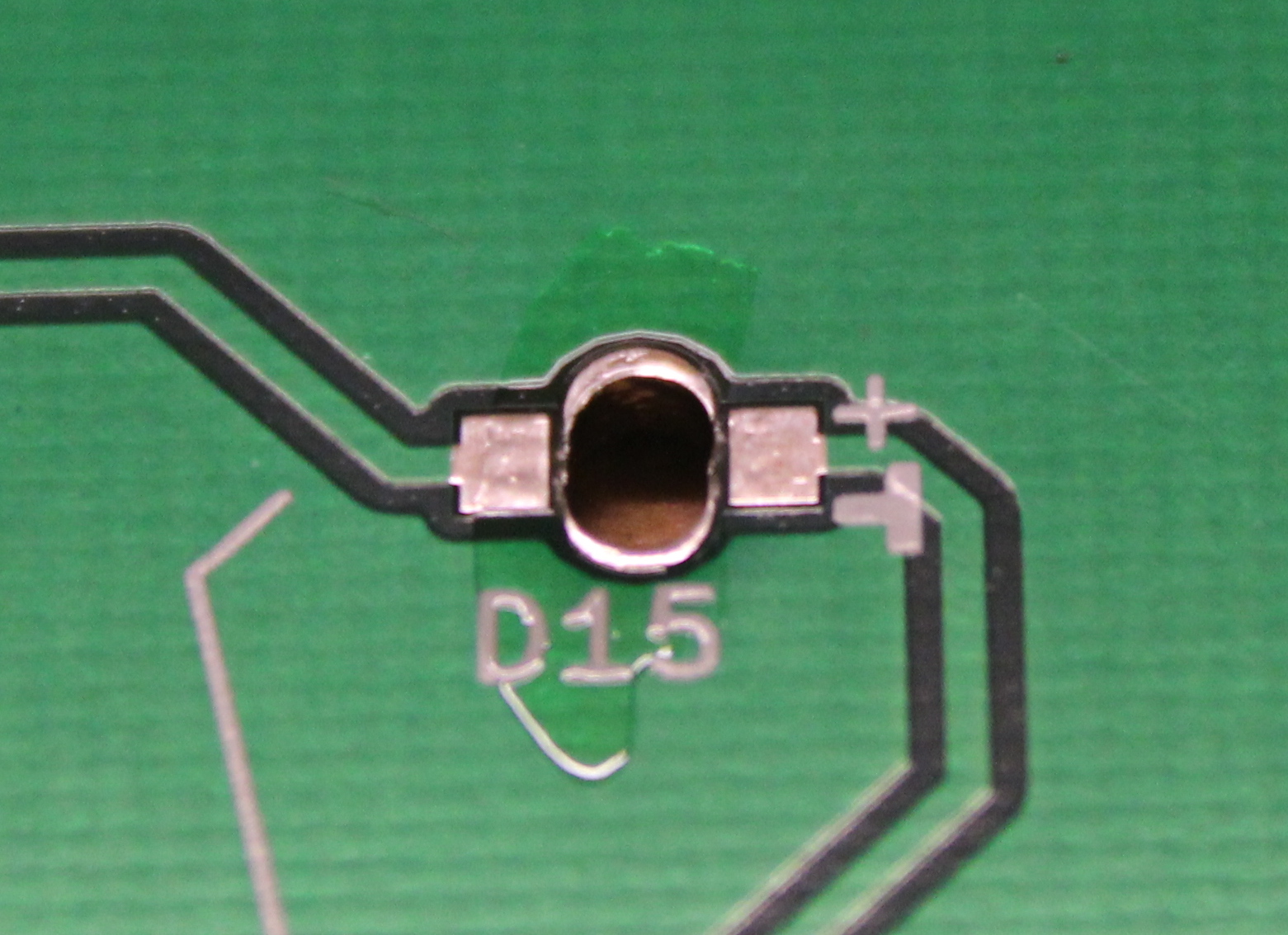

I was having trouble soldering the Rev 2 boards reliably. The major problem involved the slots for the LEDs. For these prototype boards, I needed to stick to a standard PCB fabrication process, which meant that I couldn't get non-plated slots. Unfortunately, plated slots make it very easy to short out the LEDs. To test for a short, I used my multimeter on the diode setting. If the LED lit up, there was no short; if the buzzer beeped, I needed to rework the soldering. Fixing three or four LEDs per board was very time consuming, and it took me 90 minutes to solder the first two boards together. I needed a better solution to cover the plated slots.

At this point, the nail polish came in. I used it as a sort of temporary solder mask. It stinks a bit when the soldering iron hits it, but it's not much worse than the solder itself. Out of the next eight boards, I experienced two shorted LEDs, and that improvement made the process much faster. I'm not convinced nail polish is the best solution, so if you have other suggestions, please leave a comment.